Natural Gas Liquids (NGL): Comprehensive Guide, Types, and Practical Examples

Explore natural gas liquids—key components extracted from natural gas as liquids—and learn about their types, uses, and significance in energy and industry.

What Are Natural Gas Liquids?

Natural gas liquids (NGLs) are valuable hydrocarbons extracted from natural gas in liquid form. These liquids are separated at field facilities or gas processing plants through techniques such as absorption and condensation. NGLs encompass various types, each serving distinct industrial and commercial purposes.

Understanding the Importance of Natural Gas Liquids

NGLs hold significant economic value as they are separated from natural gas and processed into different hydrocarbon components. Being hydrocarbons, they share molecular structures with natural gas and crude oil, consisting solely of carbon and hydrogen atoms.

Key Insights

- NGLs are liquid hydrocarbons derived from natural gas through separation processes.

- They have diverse applications including cooking, heating, fuel blending, and plastic manufacturing.

- Handling and transportation of NGLs can be costly due to their physical properties.

- The United States is expanding its natural gas liquids export capacity.

Classification and Uses of Different NGL Types

NGLs are categorized based on vapor pressure into:

- Low vapor pressure: condensate

- Intermediate vapor pressure: natural gas

- High vapor pressure: liquefied petroleum gas (LPG)

Although chemically similar, each NGL type has unique industrial and consumer applications.

Ethane

Primarily used as a feedstock in petrochemical industries, ethane is essential for producing plastics, antifreeze, detergents, and various synthetic materials.

Propane

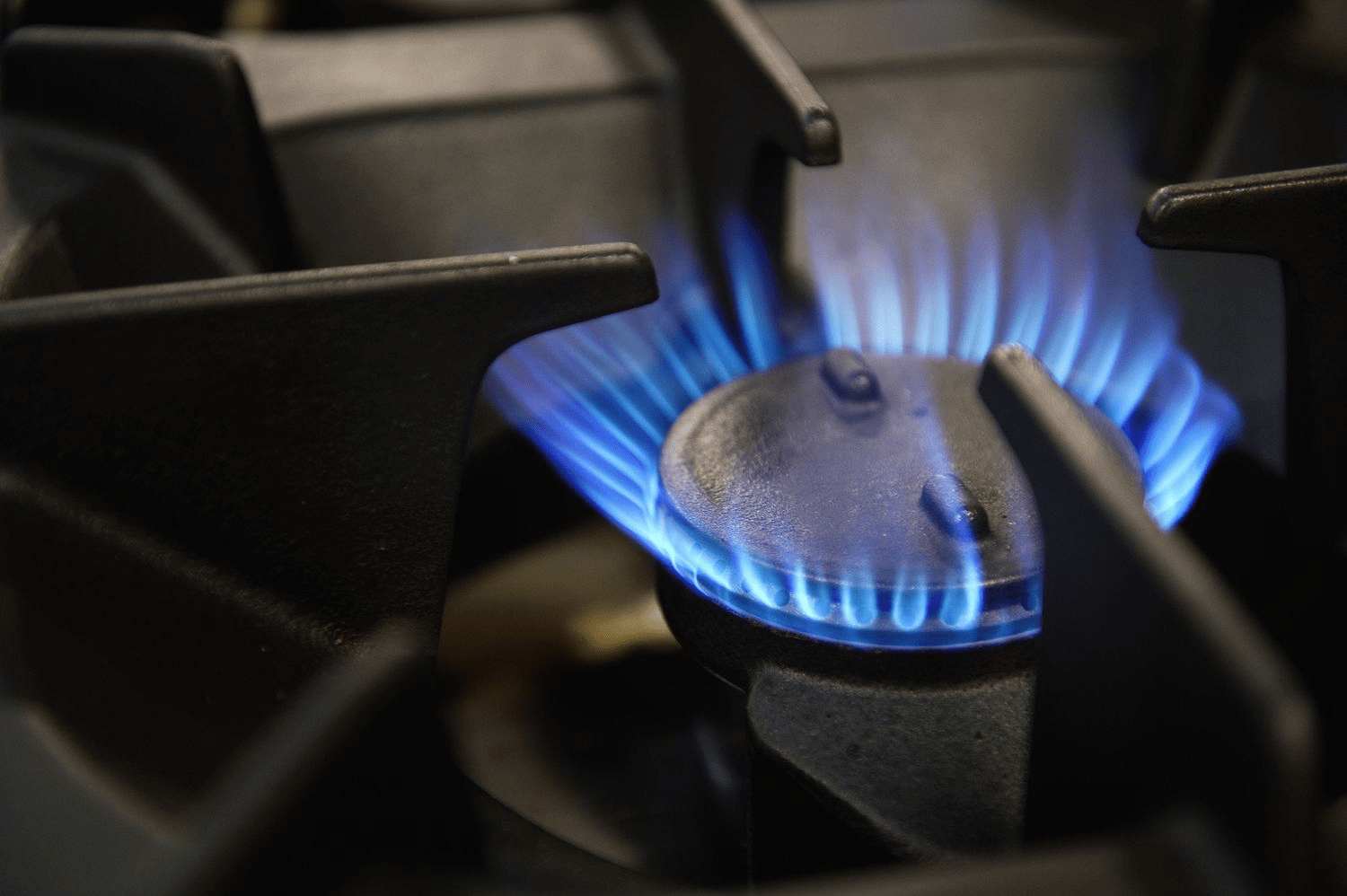

Propane serves as fuel for residential and commercial heating, cooking appliances, and some vehicles. It is also a raw material in petrochemical manufacturing.

Butanes

Butanes are blended with gasoline and propane to create products like synthetic rubber and lighter fuel. Pure butane functions as a refrigerant, and combined with propane, it forms liquefied petroleum gas (LPG).

Isobutanes

Isobutanes are utilized in refining processes and petrochemical production, contributing to aerosols and refrigerants.

Pentanes

Pentanes are components of natural gasoline and act as blowing agents in producing polystyrene foam. Pentanes plus, a variant, is mixed with vehicle fuels and used in oil sands bitumen extraction.

Opportunities and Challenges in the NGL Sector

The surge in U.S. shale gas extraction has boosted NGL production, which correlates positively with crude oil prices. Lower crude prices encourage companies to increase NGL output to balance revenue streams.

Technological advancements like horizontal drilling and hydraulic fracturing have propelled NGL availability, providing producers with additional income sources and market diversification.

However, NGLs require specialized handling due to their need for high pressure or low temperatures to remain liquid, making transportation and storage more expensive and complex. Their flammability demands stringent safety measures and specialized infrastructure.

Moreover, the volatility of NGLs restricts their market reach, and growing production necessitates expanded processing facilities to efficiently separate them from natural gas.

Advantages

- NGLs are key petrochemical feedstocks for a wide range of chemical products.

- They support applications from home heating to fuel and plastic production.

- Innovations in drilling have increased NGL availability.

- NGLs create additional revenue streams for oil and gas companies.

- The U.S. is becoming a leading exporter of natural gas liquids.

Disadvantages

- High costs and complexity in handling, storage, and transportation of NGLs.

- Requirement for controlled pressure or temperature to maintain liquid state.

- Growing demand for processing plants to separate NGLs effectively.

- Limited market due to the volatile nature of NGLs.

Real-World Examples of Natural Gas Liquids

Consider a new production facility in Texas that extracts natural gas in large volumes. The gas undergoes heating at different temperatures to separate ethane and propane.

Exxon Mobil Corporation (XOM)

As one of the largest U.S. natural gas producers, Exxon Mobil removes ethane once it reaches its boiling point, followed by propane through an extended boiling process. This fractionation separates NGLs, which are then transported via pipelines.

Specialized trucks deliver these liquids to commercial and industrial users. Propane is widely used for heating and cooking, while ethane is a crucial raw material for manufacturing plastics like bottles and bags.

Discover engaging topics and analytical content in Futures and Commodities Trading as of 14-04-2020. The article titled " Natural Gas Liquids (NGL): Comprehensive Guide, Types, and Practical Examples " provides new insights and practical guidance in the Futures and Commodities Trading field. Each topic is meticulously analyzed to deliver actionable information to readers.

The topic " Natural Gas Liquids (NGL): Comprehensive Guide, Types, and Practical Examples " helps you make smarter decisions within the Futures and Commodities Trading category. All topics on our website are unique and offer valuable content for our audience.